From produce to pharmaceuticals, global demand for reliable, sustainable refrigerated transport solutions continues to increase. Leaders at Thermo King, a worldwide leader in the design and manufacturing of sustainable climate-control solutions for refrigerated transport, saw the need to scale production capabilities to meet the growing demand and to sustain future growth.

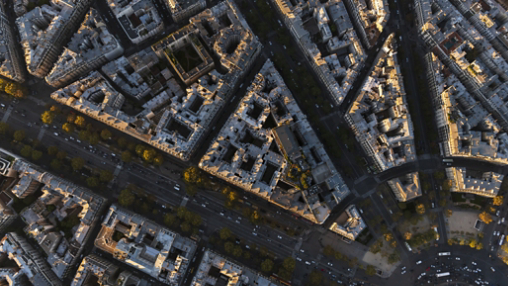

To add to production capacity at their Arecibo, Puerto Rico site, leadership began planning for an additional site that would create redundancy in the supply chain, prioritize sustainable operations and allow for additional advancements in electrification and future business growth. The team chose the growing technical hub of Greenville, South Carolina, for a new site, announcing a $30M capital commitment in March of 2022.

And then in May of 2022, a tornado touched down in Arecibo, reducing the production capabilities at the Arecibo site by nearly two-thirds.

With customer demand at the forefront, the project team jumped into action, collaborating across the Trane Technologies enterprise while taking bold steps toward sustainability and resiliency. Less than a year later, the Greenville site was fully operational and shipping product to customers.

Sustainable solutions in a changing world

Despite the rapid timeline, the project team ensured sustainability remained at the forefront. Guided by Trane Technologies’ 2030 Sustainability Commitments, they worked diligently to build a model facility for the future, prioritizing sustainable strategies and operations throughout the development, from site selection to potential future expansions.

As the existing building on the leased site was not initially designed for a climate system, the project team first constructed a building shell with HVAC requirements in mind, including an insulated reflective roof, concrete apron and reinforced roofing for rooftop units. Engineering and construction teams ensured the project would include the latest innovations in LED lighting, low-flow plumbing, high-performance window glass and energy-efficient appliances.

The facility is heated and cooled by the latest Trane AscendTM heat pump chillers and incorporates a broad range of sustainability best practices, from a reflective roof to indigenous plants integrated into the groundwater management plan.

Designed to produce Precedent S-Series trailer refrigeration units and eventually Advancer S-DRC intermodal refrigeration units, the manufacturing lines make full use of the latest technology advancements such as Automated Guided Vehicle (AGV) technology, DC torque tools and robotic welding, all of which increase precision and efficiency of operations. They can also be adapted for future products to support Thermo King’s goal of electrified solutions throughout the cold chain.

The Greenville team also piloted an advanced manufacturing execution system. Thermo King can capture detailed data on critical manufacturing processes to help control quality and ensure units are performing at peak efficiency before leaving the facility.

And with a 300,000-square-foot facility with potential for expansion, the plant can continue to grow, responding to changing circumstances with resilient operations.

Resilient teams at the ready